Zhafir at the K-Show 2022 Electrical technology to the point

2022-09-30

With three exhibits at the K-Show, Zhaifr Plastics Machinery will showcase the wide range of applications for efficient electrical solutions.

Defacto, Zhafir ranges have revolutionized the price level of electrical solutions and made them affordable for many processors in Europe in the first place. The same applies to running costs: with proven energy savings in the higher double-digit range, energy efficiency is one of the standard benefits of the Zhafir brand. At K2022, the sales team aims to convince international professionals of further benefits of their electrical technology to the point.

With its Zhafir series, Haitian International continues to provide one of the most comprehensive product families of electric injection molding machines on the market. With clamping forces from 400 to 33,000 kN and application-specific solutions from all-electric to hybrid. From “small” dynamic high-speed machines to large – yet affordable – electric injection units. Zhafir machines operate very precisely and extremely energy-efficient with up to 70% compared to traditional drive concepts.

At K 2022, Zhafir will present its wide range of applications by means of three exhibits, most of them with automation. All exhibits will be live networked with 2 MES systems each. One of these is the MES from ICON s.r.l., Italy – Haitian International Germany ‘s new cooperation partner for the European market. The free process monitoring system “Go Factory 2.0” from Haitian Smart Solutions, currently available for the Chinese market, will also be presented.

Zhafir Zeres Multi – European premiere as R version

The electric Zeres series as a multi-component solution, to be experienced in Europe for the first time as an R version. Highlights: small footprint, high flexibility for automation integration, easy access to mold area, adaptable for 1K or 2K.

Live application of the Zeres Multi:

A ZE3000M-830-R430 produces a tape measure housing on a 4+4 index plate made of ABS/TPE.

TPE from K-D. Feddersen , the ABS is provided to INEOS Styrolutions. Their recycled specialty ABS copolymer “Novodur ECO” is also making its debut at the K show.

The components will be demolded using a Hilectro V1100ID from Haitian Smart Solutions.

Zhafir Zeres Medical – for clean production

The successful Zeres with certified medical package is increasingly in demand for clean applications. Designed to meet the industry’s high production standards, the medical version brings a whole bundle of turnkey solutions for clean production to the table. Thanks to integrated hydraulics, it is ideally suited for molds with core pulls.

Live application of the Zeres Medical:

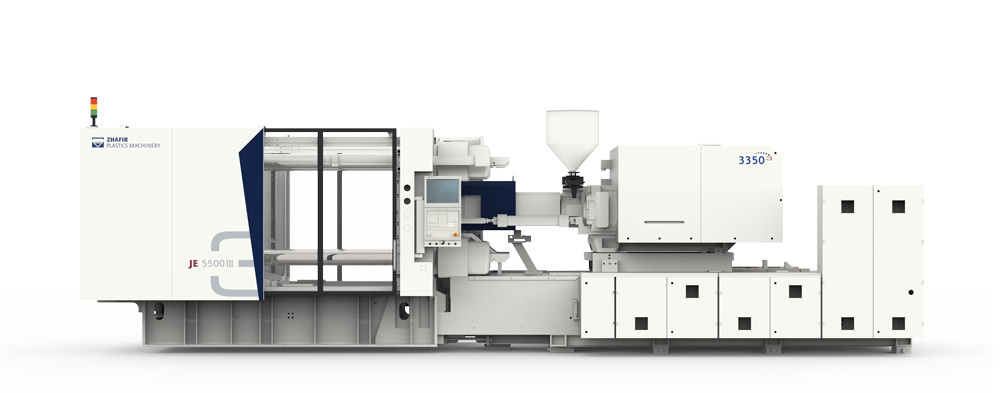

Zhafir Jenius Series – the hybrid two-platen solution

With clamping forces ranging from 3,600 to 33,000 kN, the space-saving Jenius Series represents a wide range of clamping forces and broad application versatility. The Jenius was developed to meet the specific quality requirements of, for example, white goods or the automotive industry. With excellent stability, higher efficiency and high ROI.

Live application of the Jenius:

The molded part is removed using a Success 33 from Sepro. MOL supplies the PP GF 30 regranulate and recycles the produced parts on site for further use. Material handling and cooling are provided by Piovan.

Haitian International at K 2022: Hall 15 / Stand A57

Zhafir Zeres Multi Series –

The electric multi-component solution in R-position

Zhafir Zeres Series –

Medical package for clean production

Zhafir Jenius Series –

The hybrid two-platen solution