„SIGNIFICANT ENERGY SAVINGS WITH THE ZERES“

2019-10-08

Interview at Spritzgussa Plastics GmbH & Co. KG

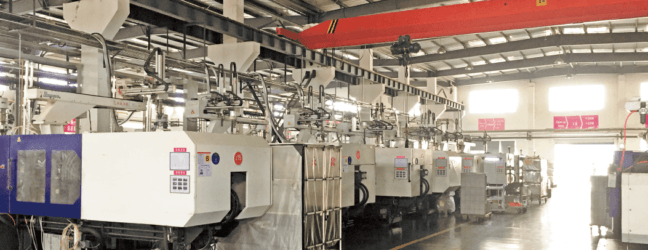

Spritzgussa Plastics GmbH & Co. KG is one of the most experienced manufacturers of packaging for food, non-food, cosmetics and consumer goods. Sustainability aspects such as resource conservation or recycling play a special role here. At the end of 2018, the first Zhafir Zeres series came on board, the second followed in May 2019. Both times the delivery, installation and system start took place extremely fast and flawless. Time for a first evaluation.

We talked to Joachim Stelzer, Head of Sales and QA, and Jochen Bartl, Managing Director and Head of Production, about internal adjustments towards a more environmentally friendly production method and the advantages of the electric Zeres Series.

Mr. Stelzer, everyone is talking about sustainability. How does Spritzgussa feel about this?

“We see sustainability as one of our main topics for the coming years. But: Blind actionism does not help much. The industry must provide serious answers. Not only in food packaging, but also for consumer goods. But especially in food packaging, due to food contact, we are very limited because of strict regulations.”

What potential do you see for biobased plastics?

“Bio-based plastics are not a long-term solution. It also decomposes into small particles, which are still plastics, only smaller. It is also not compostable in the usual sense.

Where do you think the plastics industry can start?

“First of all in the general attitude. For us, the preservation of our environment is a matter of the heart. We continuously try to optimize the energy consumption per ton of plastic granulate and the CO2 emissions. Waste products that we produce are returned to the recycling cycle. A PET bottle does not find its way into the sea by itself. Here, everyone who picks up a bottle has to take responsibility and act accordingly.”

Where do you see internal adjustments for more sustainability?

“There are many. Energy consumption is a big issue for us, also a purchasing criteria. Then last year, for example, we integrated a heat recovery system. Energy is becoming more and more expensive and therefore more important. We produce large quantities with fast cycles, so the process and energy consumption must be optimally coordinated so that the profit margin can be achieved. That is why we are switching to electrical machines. Until now, we only had hydraulic premium brands, now we have switched to Zhafir.”

“Zhafir machines are compact and uncomplicated, I like that. Retrofitting simple functions is absolutely easy and affordable at Zhafir – worlds away from the norm.”

What was the decisive factor?

“The efficiency is significantly higher. In addition, there is easier maintenance due to fewer moving parts, longer maintenance intervals, so that maintenance costs stay manageable. Cleanness is also a major issue, especially in our production for food packaging. Oil always carries the risk of leakage, but our production must remain clean.”

What advantages do you see in performance?

“The machines are obviously quieter, precise in their movements and, as I said, efficient and economical. In a mold test with hydraulic machines, we measured energy savings of up to 65%. We have become real fans and in the next few years we will replace our entire portfolio with electric machines from Zhafir. Because the Zhafir machine is also unbeatable in price”.

How do you rate Zhafir’s service and support?

“Our demand on Zhafir is clearly defined: carefree production. The two machines run 52 weeks in a row. They must meet all requirements and deliver the best possible quality at the lowest possible maintenance costs. Both Zeres machines have done this so far. But of course service and support are important. We feel very comfortable with Hewaco. It is a very cooperative relationship. If we have any questions, they come immediately. Apart from that, we do a lot ourselves and also have mechanics in-house. The flexible spare parts policy of Haitian International Germany is very helpful in this case. In this area, Zhafir is pursuing a different, unique strategy in Germany.”

Significant advantages in energy consumption:

A comparison of the Zhafir Zeres Series with a hydraulic high-speed machine from Europe in the same tonnage. The lid (picture above) is produced. All machines run with a cycle of 7.5 seconds, according to Mr. Stelzer a normal cycle time for this product.