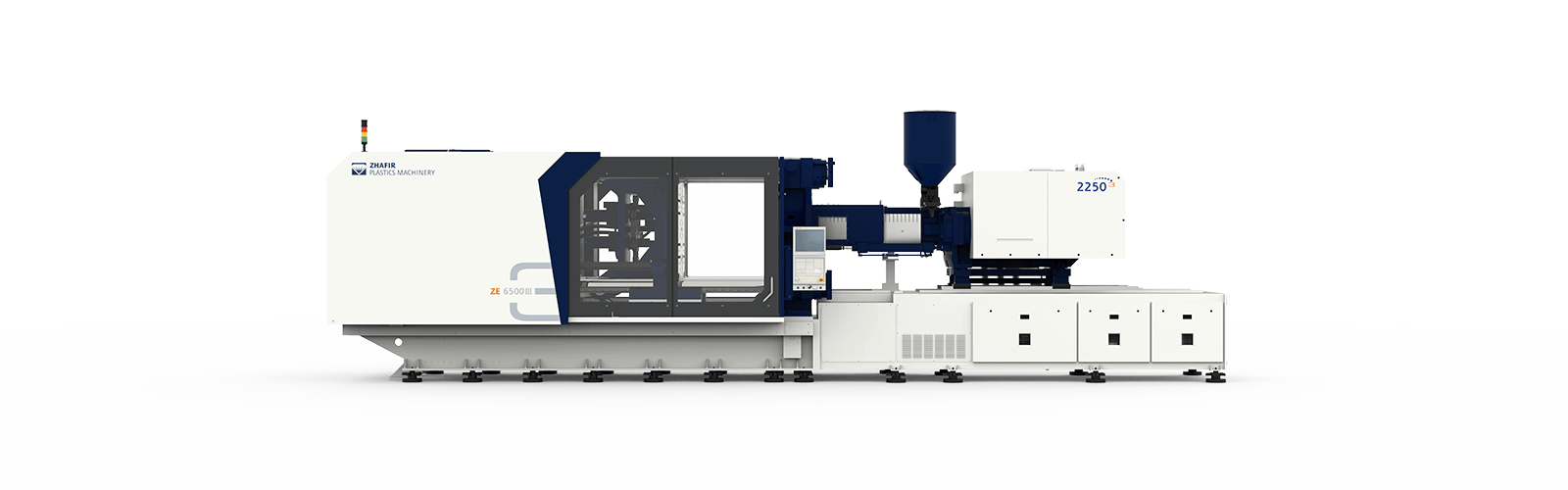

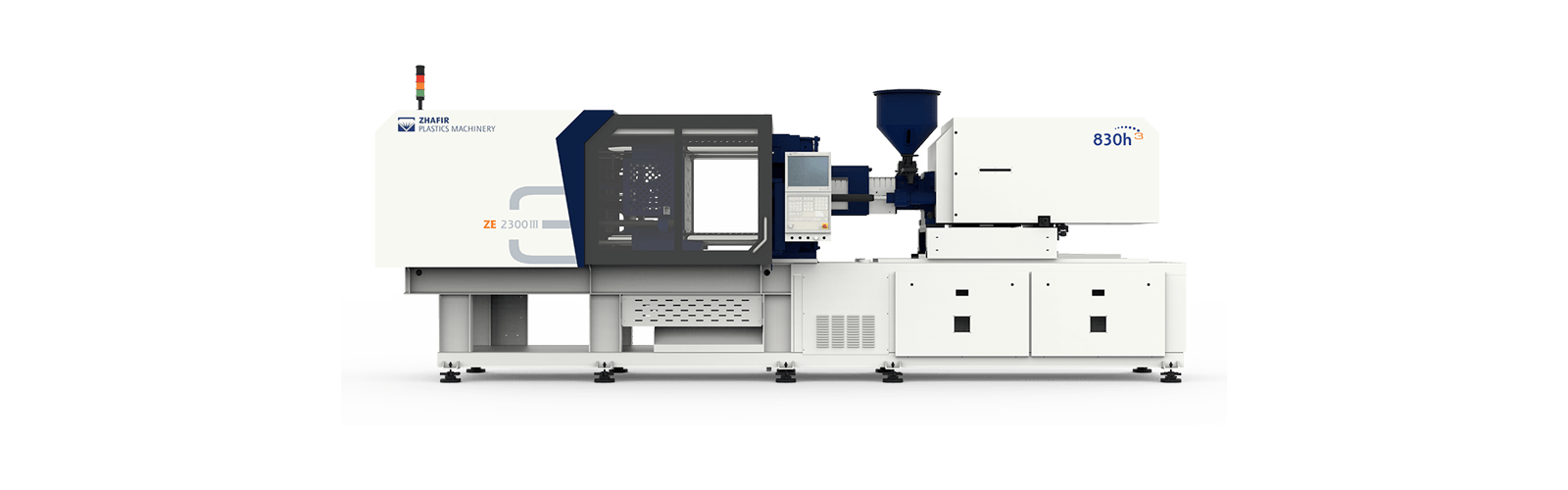

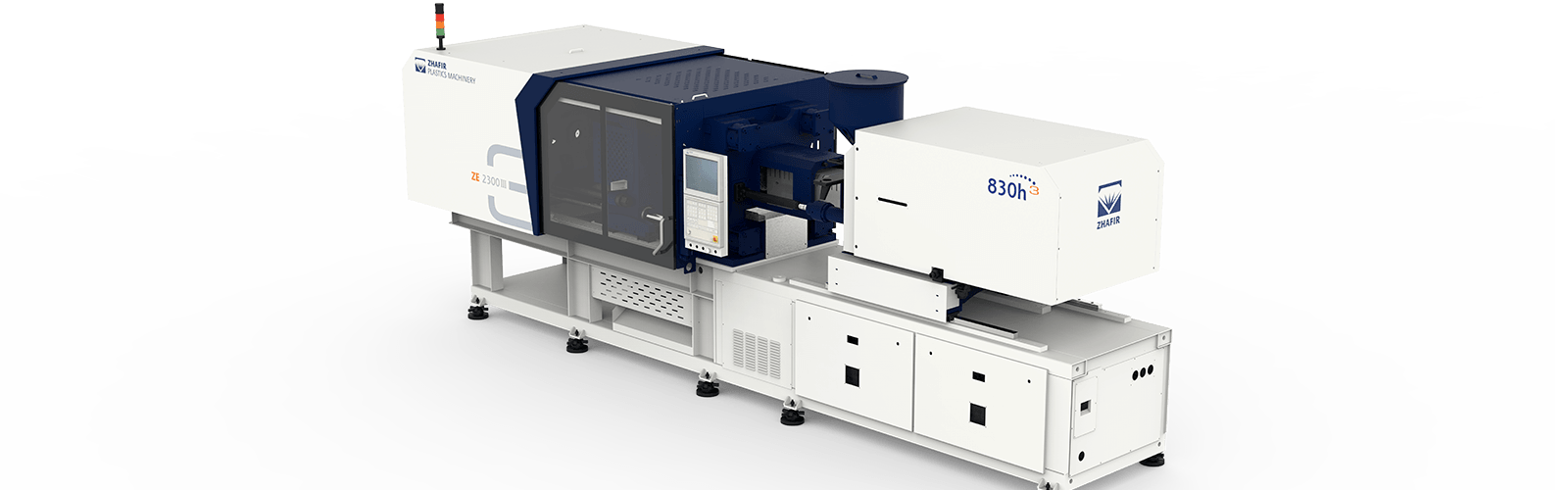

Zeres III Series

ELECTRIC. FLEXIBLE & EFFICIENT

The Zeres Series builds a bridge from electric injection molding technology to traditional hydraulic machine applications. Identical in construction to the Venus Series, it also has integrated servo-hydraulics. Main movements such as mold and injection are electric, side axes such as nozzle movement, core puller and ejector are servo-hydraulic. In this way, the Zeres gives the processor not only the wide electric range of applications but at the same time also more production efficiency because of energy savings in the double-digit percentage range. Currently, the Zeres Series is available in clamping forces from 400 to 13,800 kN.

PRECISE + INTELLIGENT+ INTERACTIVE+

Tailor-made electrical servo drive systems in combination with a new inverter generation enables a high-performance and unique price/performance ratio with high precision and dynamics. The 3rd technology generation of Zhafir is a system platform with intelligent and extremely fast adaptive software. The Zeres Series enable extremely open integration and connectivity with all common interfaces and seamless connection of industrial automation or any MES system.

Tailor-made electrical servo drive systems in combination with a new inverter generation enables a high-performance and unique price/performance ratio with high precision and dynamics. The 3rd technology generation of Zhafir is a system platform with intelligent and extremely fast adaptive software. The Zeres Series enable extremely open integration and connectivity with all common interfaces and seamless connection of industrial automation or any MES system.

ELECTRIC. FLEXIBLE & EFFICIENT 400 – 13,800 kN

- Integrated hydraulics for extended application variety

- Intelligent motion control for short dry cycle times

- Tailor-made servo drives

- Square tie bar distance for more freedom

- Linear guides (optional)

- Intelligent mold protection

- Application-oriented injection units

- Latest control technology