Zhafir Multi Solutions

Technology to the point

Electrical multi-solutions from Zhafir offer all the advantages of electrical machine technology: precise, quiet, energy-saving, maintenance-friendly and extremely flexible integration into upstream and downstream automated production processes. Although any multi-component product can be achieved with any of the following injection unit layouts, the most suitable solution for the actual operating conditions should be selected to reduce time and economic costs. Our experts are always available for product analysis.

Plug & Play

Electric injection units from Zhafir were designed as independent modular components with their own power and drive sources. They can be adapted to different Zhafir machine models for increased flexibly across several machines on your production floor.

L

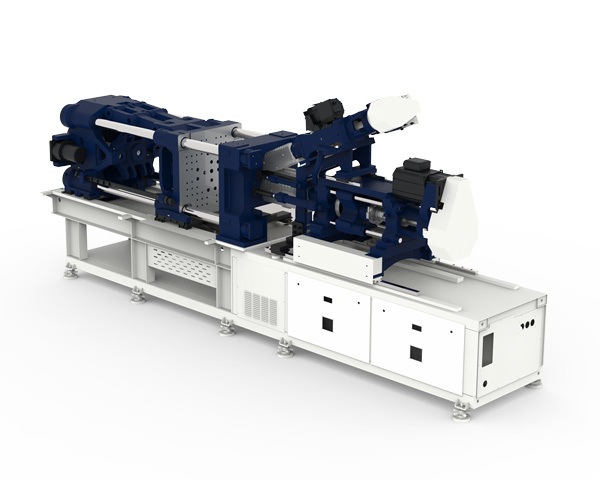

HORIZONTAL LATERAL LAYOUT

FEATURES

» Flexible and available on all Zhafir standard Series

» Compact and steady mechanical structure

» Electric technology on secondary injection unit: all electrical dosing, plasticizing and injection

» The nozzle position of second injection unit is horizontally adjustable

» Second injection unit designed for easy and quick access

» The injection unit control is integrated into the main machine unit

» Optional: electric rotary table or platen index on the movable platen

» Optional: protective housing

![]()

![]()

![]()

L

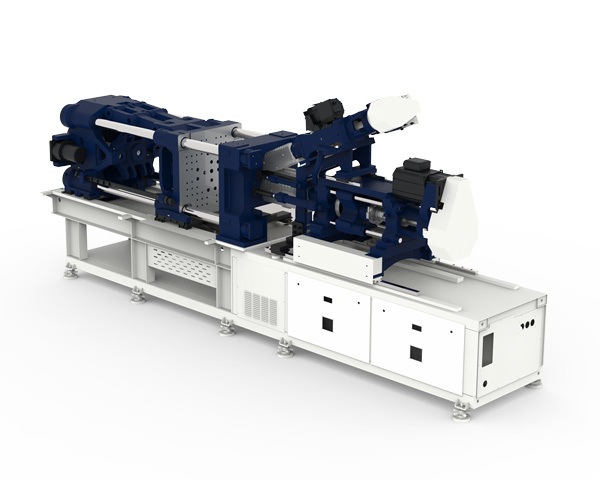

HORIZONTAL LATERAL LAYOUT

FEATURES

» Flexible and available on all Zhafir standard Series

» Compact and steady mechanical structure

» Electric technology on secondary injection unit: all electrical dosing, plasticizing and injection

» The nozzle position of second injection unit is horizontally adjustable

» Second injection unit designed for easy and quick access

» The injection unit control is integrated into the main machine unit

» Optional: electric rotary table or platen index on the movable platen

» No height requirement

» Optional: protective housing

![]()

![]()

![]()

V

VERTICAL LATERAL LAYOUT

FEATURES

» The additional injection unit can be mounted vertically on the fixed clamping platen, it can be moved horizontally for easy mold changes

» Flexible and available for all Zhafir standard series

» Electrical technology on the additional injection unit: fully electric metering, plasticizing and injection

» Optional: external HMI for the additional injection unit

» Optional: electric turntable or indexing platen

![]()

![]()

![]()

V

VERTICAL LATERAL LAYOUT

FEATURES

» The additional injection unit can be mounted vertically on the fixed clamping platen, it can be moved horizontally for easy mold changes

» Flexible and available for all Zhafir standard series

» Electrical technology on the additional injection unit: fully electric metering, plasticizing and injection

» Optional: external HMI for the additional injection unit

» Optional: electric turntable or indexing platen

![]()

![]()

![]()

P

PARALLEL LAYOUT

FEATURES

» Two injection units are placed horizontally parallel next to each other

» Parameters based on the ZE injection unit

» The servo-electric rotary table offers high precision and dynamics

» Dual ejector system is servo-hydraulic and controlled independently

» The powerful dual-CPU guarantees fast response times

![]()

![]()

P

PARALLEL LAYOUT

FEATURES

» Two injection units are placed horizontally parallel next to each other

» Parameters based on the ZE injection unit

» The servo-electric rotary table offers high precision and dynamics

» Dual ejector system is servo-hydraulic and controlled independently

» The powerful dual-CPU guarantees fast response times

![]()

![]()

R

PARALLEL LAYOUT

FEATURES

» Secondary injection unit placed above the main unit

» Extremely compact and space-saving, flexible and available on all Zhafir standard Series

» Electric technology on secondary injection unit: all electrical dosing, plasticizing and injection

» Optional: electric rotary table or platen index

![]()

![]()

![]()

R

PARALLEL LAYOUT

FEATURES

» Secondary injection unit placed above the main unit

» Extremely compact and space-saving, flexible and available on all Zhafir standard Series

» Electric technology on secondary injection unit: all electrical dosing, plasticizing and injection

» Optional: electric rotary table or platen index

A

ASPECTANT LAYOUT

FEATURES

» Two sets of electric injection units arearranged in opposite directions

» Significant increase in mold area utilization

» Significant reduction in clamping force requirements

» The force of the clamping unit is more uniform

» Multi system synchronous control to reduce cycle time

» Solutions for injection molding on com plex molds

» Standard spring mold function, wide application range

» Meet the needs of large-scale two-colorproducts

(Only availabe for Zhafir Jenius Series)

![]()

A

ASPECTANT LAYOUT

FEATURES

» Two sets of electric injection units arearranged in opposite directions

» Significant increase in mold area utilization

» Significant reduction in clamping force requirements

» The force of the clamping unit is more uniform

» Multi system synchronous control to reduce cycle time

» Solutions for injection molding on com plex molds

» Standard spring mold function, wide application range

» Meet the needs of large-scale two-colorproducts

(Only availabe for Zhafir Jenius Series)

![]()